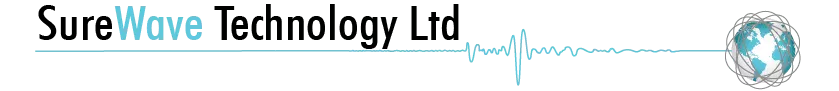

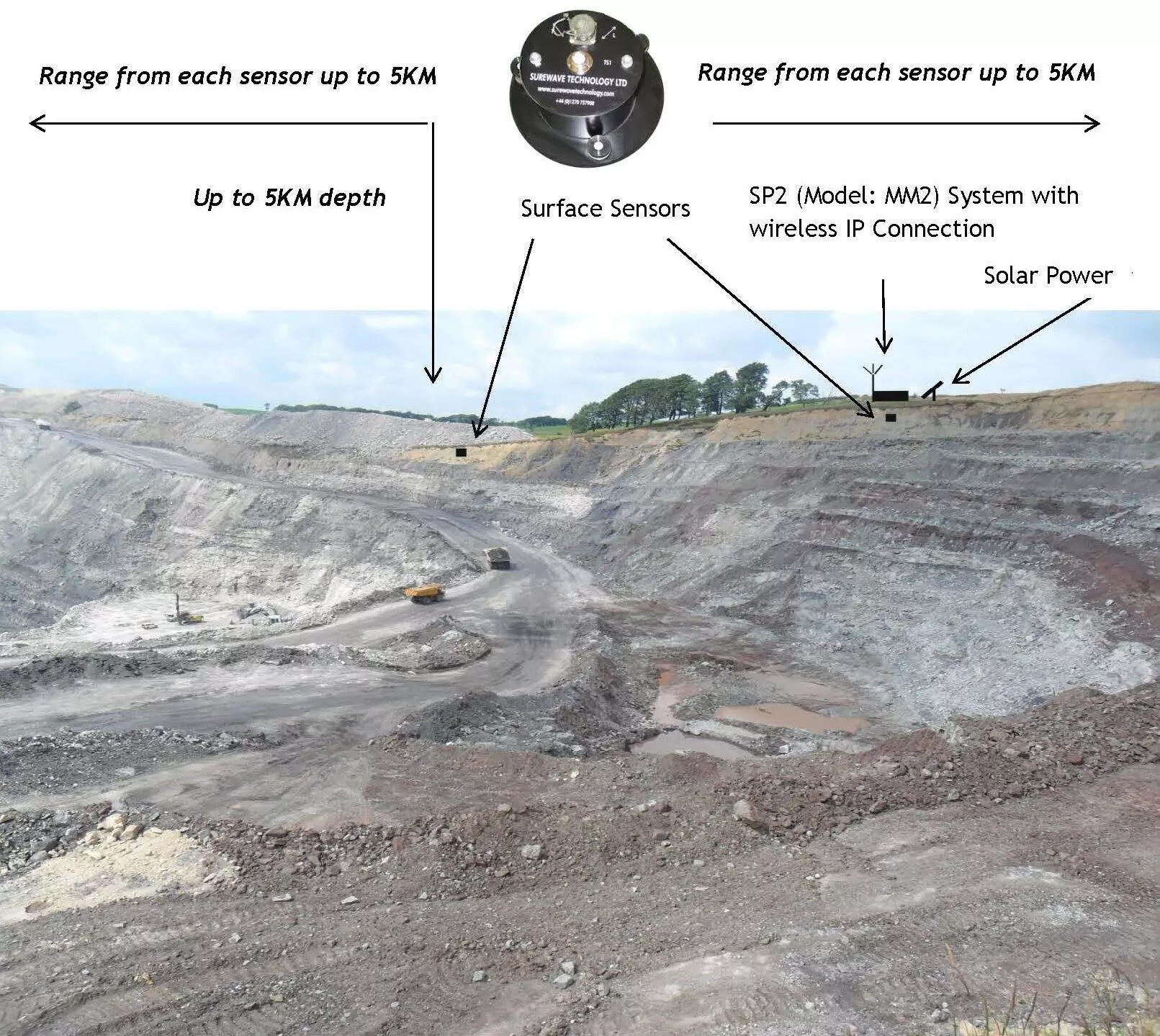

SP2’s remarkable and unique technology can be used to continuously monitor and detect microseismic events occurring within the slope walls of open cut mines and other surface material deposits such as levees, giving advance warning of internal movement and the potential for collapse.

Each sensor is capable of detecting microseismic events up to 1 km horizontally and below ground. This eliminates the need for bore holes.